OEM

KNF pump in galvanizing industry

KNF pump in galvanizing industry

Introduce KNF pump in galvanizing industry

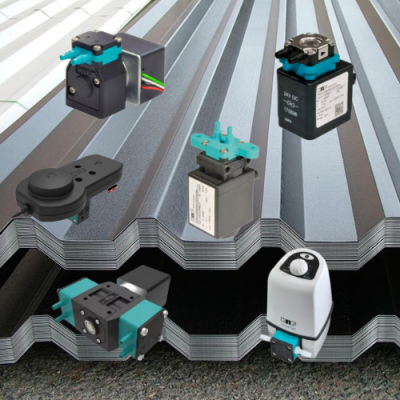

KNF pump in galvanizing industry, galvanizing is the process of coating a thin layer of zinc on the metal surface to protect from corrosion. To ensure the performance and quality of this process, the use of high quality pumping equipment is important. KNF pump, with its outstanding features, has become the optimal solution in galvanizing. This article will introduce the application of KNF pumps in this process, to provide useful information for businesses and manufacturers..

Outstanding features of KNF pumps in the galvanizing industry

- Good Chemical Resistance:

- KNF pumps are designed with chemical-resistant materials, ensuring the pump can operate well in highly corrosive galvanized environments..

- Materials such as PTFE, PVDF, and stainless steel enhance pump durability and longevity.

- High precision:

- KNF pump provides stable flow and pressure, ensuring precise mixing ratio between zinc and other additives.

- This helps improve plating quality and minimize material waste.

- Easy Maintenance and Operation:

- The compact and smart design of the KNF pump makes it easy to install and maintain.

- Parts are easy to replace, helping to reduce machine downtime and increase production efficiency.

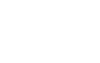

Specific application of KNF pump in galvanizing phase

- Preparation of Galvanizing Solution:

- KNF pumps are used to mix the galvanizing solution ingredients precisely.

- Ensure uniformity and quality of plating solution.

- Providing Galvanizing Solution:

- KNF pump is responsible for providing galvanizing solution into the plating tank with stable flow and pressure.

- Ensure the plating process takes place continuously and effectively.

- Vacuum and Reuse Plating Solution:

- KNF pump can suck and reuse galvanizing solution. Helps save costs and minimize environmental impact.

- Ensuring clean and sustainable production processes

Benefits of using KNF pump in interstitial plating

- Enhance Product Quality:

- The KNF pump helps maintain mixing and solution delivery precision, thereby improving the quality of the zinc coating.

- After plating, the product has high durability and beautiful aesthetics.

- Optimize Production Process:

- Using KNF pumps helps optimize production processes, minimize machine downtime and increase efficiency.

- Create favorable conditions for expanding production scale.

- Cost savings:

- Reusing plating solution and minimizing waste helps save on raw material costs.

- KNF pumps have long life and low maintenance costs, minimizing long-term operating costs.

Conclusion KNF pump in galvanizing industry

KNF pumps are the ideal solution for businesses in the galvanizing industry. With chemical resistance, high precision and easy maintenance, KNF pumps not only improve product quality but also optimize production processes and save costs. Investing in KNF pumps is a smart step to improve efficiency and competitiveness in the market.

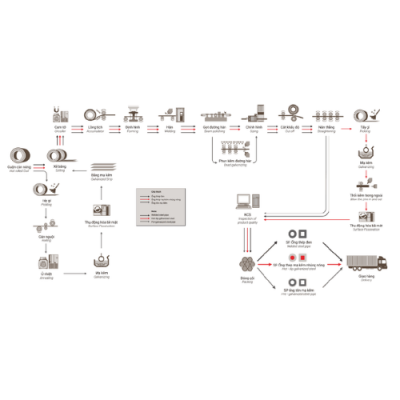

List of product codes applied to the galvanizing industry

| NF 300 RC |

| 10 FEM 1.10 RC-P |

| FF 12 |

| NF 1.10 |

| FL 10 |

| NF 5 |

| FP 7 |

→ See more KNF pump products Here.