OEM

KNF pump in cement production

KNF pump in cement production

Introduction

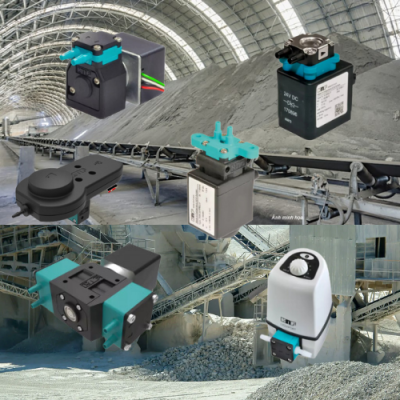

KNF pump in cement production, The cement manufacturing industry requires precise and efficient processes to produce high-quality products to meet growing construction demands. During cement production, the use of high-quality pumping equipment is vital to ensure processes run smoothly and efficiently. KNF pumps, with outstanding features, have become the top choice for applications in the cement production industry. This article will introduce in detail the application of KNF pump. In cement production, helping businesses better understand the benefits that KNF pumps bring..

Outstanding features KNF pump in cement production

- High precision:

- KNF pump provides stable flow and pressure. Ensure the correct ratio between components in the cement production process.

- Helps create cement products with consistent and stable quality.

- Good Chemical and Temperature Resistance:

- Designed to withstand chemicals and high temperatures during the cement production process.

- Durable materials such as PTFE and stainless steel help the pump operate stably in harsh environmentsv.

- Easy to Maintain and Clean:

- The smart design of the KNF pump makes it easy to disassemble and install. And hygiene, ensuring the production process is always clean and efficient.

- Easy-to-replace parts reduce maintenance time and increase operating efficiency.

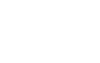

Application KNF pump in cement production

- Raw Material Mixing Process:

- KNF pumps ensure precise mixing ratios between raw materials such as clinker, gypsum, and additives.

- Helps optimize the production process and ensure cement quality meets the highest standards.

- Transportation of Raw Materials:

- KNF pumps are used to transport materials from storage to production areas quickly and efficiently..

- Ensures continuous material flow, minimizing waiting times and increasing productivity.

- Cleaning System:

- KNF pumps support production equipment cleaning systems, ensuring equipment is always clean and free of contamination.

- Helps maintain a safe production environment and adhere to strict hygiene standards.

Benefits of using KNF pumps in cement production

- Improve Product Quality:

- Helps maintain stability in the production process, creating cement products of uniform and high quality.

- Ensure cement has good durability, smoothness and adhesion, in accordance with strict construction standards.

- Optimize Operational Performance:

- Using KNF pumps helps optimize production processes, minimize waiting times and increase production speeds.

- Ensure production lines operate continuously and effectively, increasing business productivity.

- Save Maintenance Costs:

- KNF pumps are highly durable and easy to maintain, helping to reduce maintenance and equipment replacement costs.

- Ensure production equipment operates long-term and stably, reducing operating costs.

Conclude

KNF pumps are the ideal solution for businesses in the galvanizing industry. With chemical resistance, high precision and easy maintenance. KNF pumps not only improve product quality but also optimize production processes and save costs. Investing in KNF pumps is a smart step to improve efficiency. And compete in the market..

List of product codes used in cement production

| NF 300 RC |

| 10 FEM 1.10 RC-P |

| FF 12 |

| NF 1.10 |

| FL 10 |

| NF 5 |

| FP 7 |

→ See more KNF pump products Here.